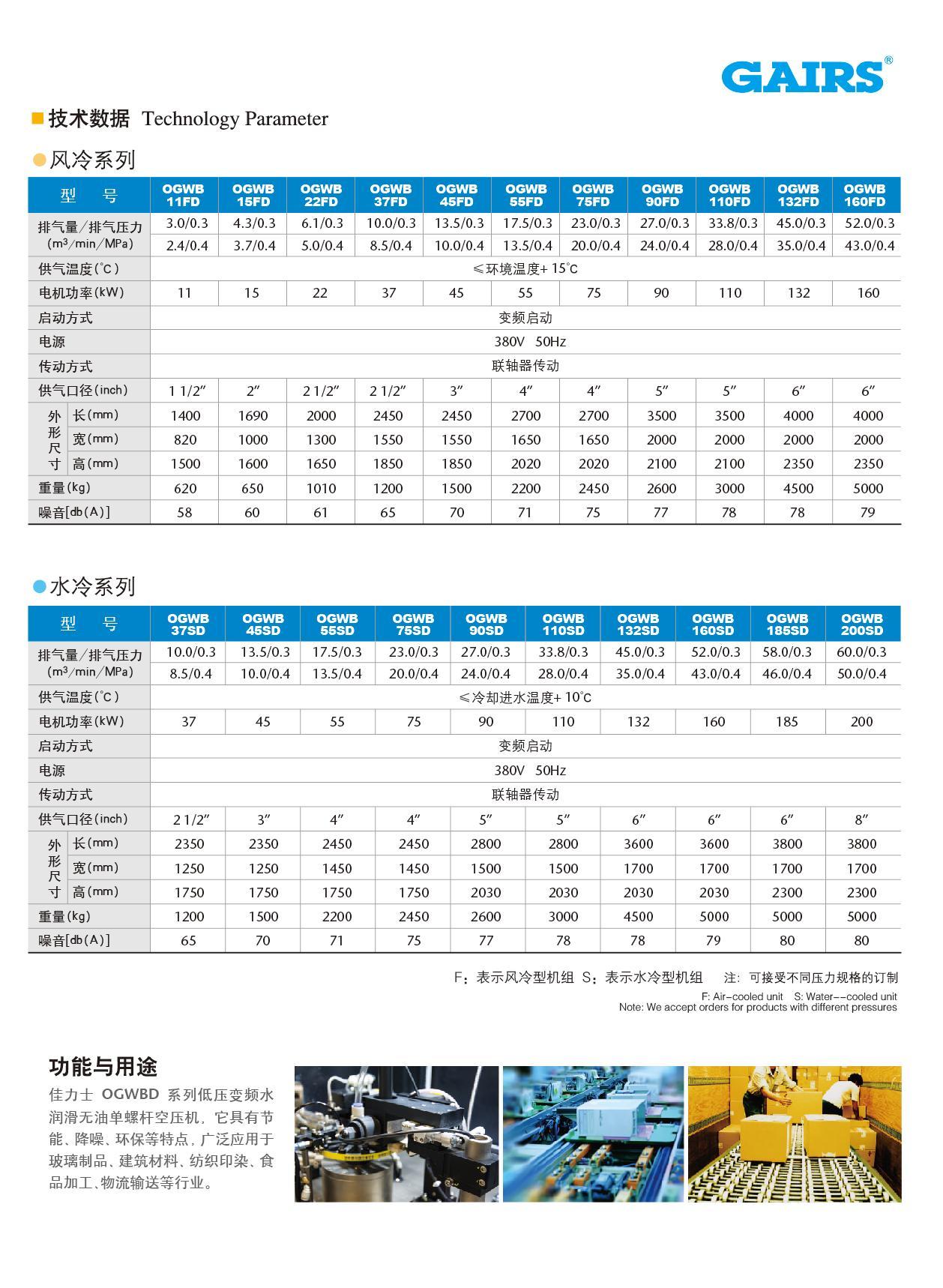

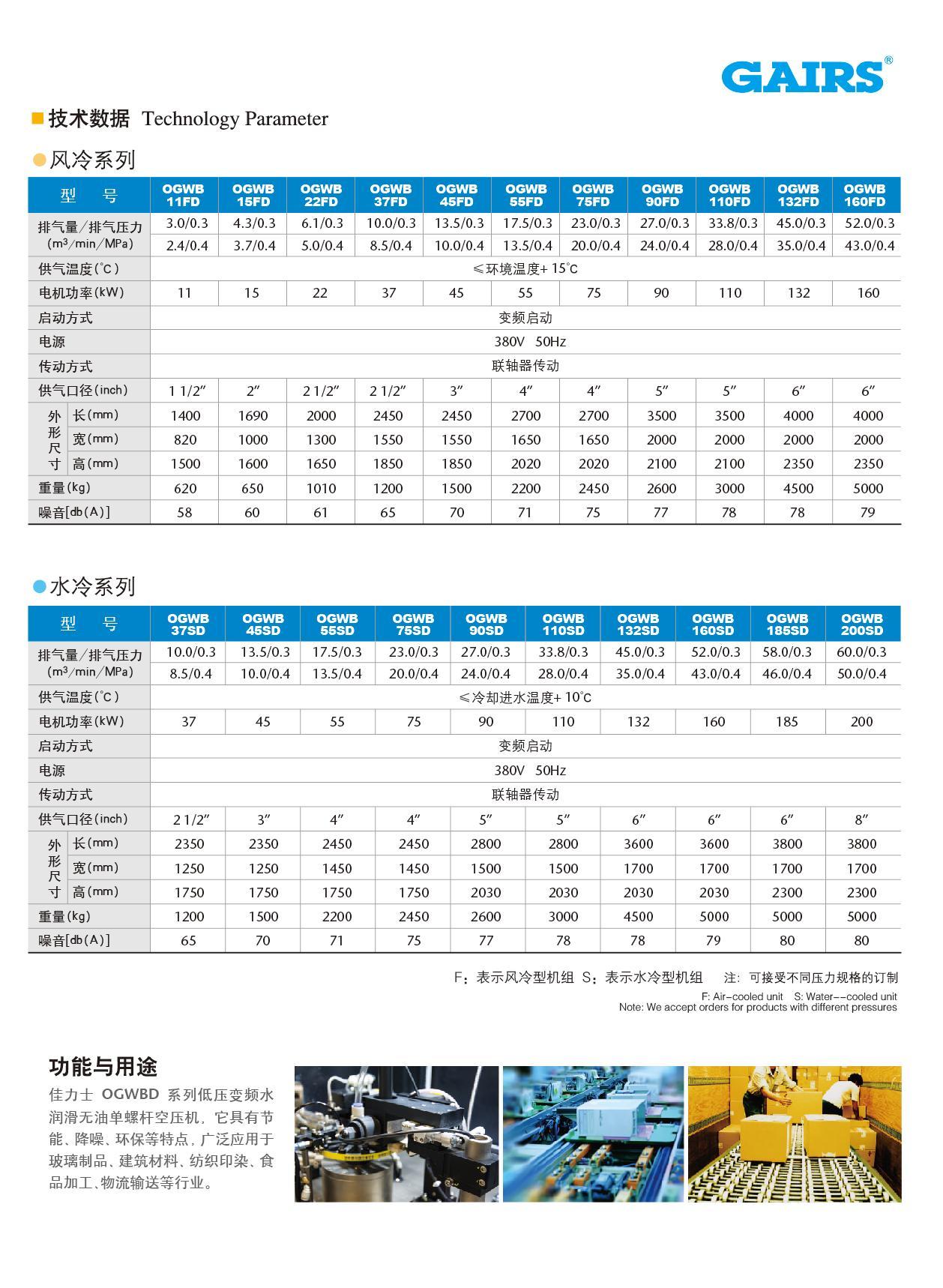

OGWBD系列水潤滑無油單螺桿變頻低壓空壓機

產(chǎn)品留言

歡迎來電洽談咨詢

地址:上海市松江區(qū)石湖蕩工業(yè)區(qū)唐明路518號

網(wǎng)址:http://www.huayuanbaobao.cn

E-mail:[email protected]

電話:021-57841111

掃碼添加聯(lián)系我們

OGWBD系列水潤滑無油單螺桿變頻低壓空壓機

產(chǎn)品留言

歡迎來電洽談咨詢

地址:上海市松江區(qū)石湖蕩工業(yè)區(qū)唐明路518號

網(wǎng)址:http://www.huayuanbaobao.cn

E-mail:[email protected]

電話:021-57841111

掃碼添加聯(lián)系我們